Foam or thermoformed inserts ensure the optimal presentation and protection of your products in cases and boxes. To offer you a complete service, you can also affix your logo, text or image on your cases.

Check out our article on exterior branding.

From prototyping to fixation, we answer all your questions in this article!

An insert is placed inside the suitcase to support, protect and aesthetically present devices, instruments and products. You can add an insert to each of our cases by different means to adapt them to your needs.

The choice of materials for inserts depends on the products, their weight and the use that will be made of the case. Inserts are tailor-made by our teams to support, protect and present in the best possible way your products, tools or samples.

For a minimum of 100 items, we offer you the following customised settings:

Flexible or rigid foam (PU/PE/PTZ): a simple shape in the size of the box, flat or dimpled (diamond/pin pattern) with pre-cut studs, foam-cut to the shape of your products by stamping, deformation or milling. Branding is possible on foam with a special coating or by laser engraving.

Thermoformed tray with cells in the shape of your products from a plastic plate (PS, PVC, ABS smooth or grained, matt or glossy) that is deformed when hot. Branding by screen printing or engraving in the mould is also possible on the thermoformed tray.

Other types of fixtures: separators, plastic pouches, dividers, plastic partitions, velcro tape, etc.

All inserts are manufactured in France, providing excellent quality and reproducible identically over time, as well as the possibility of continuous controlling the insert.

Numerous insert possibilities are available for our cases, and each insert has its specific utility:

Foam inserts are recommended for all types of products, as they are easy to manufacture and we can adapt to the density of the foam to the weight of the products. Depending on the needs (products, quantities, budget, aesthetics and use of the case), we offer machined, stamped and water-jet cut foams or foams obtained by deformation. Foam inserts also offer a good possibility for customisation because you can choose the colour of the insert to match the outside of the case. These inserts are both affordable and adaptable to numerous uses.

Thermoformed inserts are more rigid and more suitable for use in sectors with hygiene and special sterilisation requirements. One of the advantages of this type of insert is the ease with which it can be cleaned and/or disinfected. This solution is perfectly suited to the medical, food, dentistry and veterinary sectors, but it is also suitable for any other sector of activity.

In industry, for example, for heavy or cutting products, or kitchen accessories, a sufficiently thick-grained material is used. This solution is more economical, but requires manufacturing a large volume of cases to amortize the tooling costs.

The other developments are more suitable for very specific projects, with more complex and relatively unique technical constraints. Plastic dividers and partitions are, for example, more advisable for storing and filing documents, or for separating bulk products in the lid.

You can also mix different inserts by combining, for example, a spacer and thermoformed inserts if you want to include documentation with your products.

The annual volume of the project is also important because the cost of the tooling (essential for making an insert) is variable according to the processing techniques.

We will guide you in this choice and also offer you support for an optimal layout of the contents of your case.

You will also find the R2C model for pre-designed and pre-installed compartments.

Before choosing a case, we advise you to group all the products, tools or samples you want to put inside the case and determine the space you need so that all your objects are placed comfortably in it. If you do not yet have your products, a diagram with the dimensions of your products may suffice to estimate the necessary dimensions.

To select your case, enter its desired dimensions in our search engine “Find your case” or in the filter on the “All products” page. You will find all the dimensions of each case in the “specifications” tab or by downloading the product sheet.

You can then customise the exterior of the case or add the case directly to your cart. To add an insert, simply tick “yes” to the “insert” request. Following your request for a quote, a member of the sales team will contact you. Ideally, it is best to send us the products you wish to put in your case so that our team can make you a suitable proposal. If this is not possible, please send us the following information:

A list of products with their dimensions (L x W x H)

The weight of each product

A layout plan for the case (if you want a particular layout of the objects in the case)

The allocated budget

We also need to know the number of cases required (per delivery and per year) as well as the use of the case (frequency, conditions, etc.) and possibly the type of insert required (more or less dense foam, thermoformed foam, a separator, etc.).

If you choose a foam insert, you are provided with a prototype, the cost of which will be based on its complexity. For a serial order, the supply of a prototype for acceptance is included in the offer. Development of a prototype is possible after validation of the quote.

After receiving your quote request, our team will get back to you to discuss the most suitable insert options for your project and provide you with advice on the selection of your type of insert. You will be able to talk with experts to find the best compromise according to your requirements.

You can contact us today to explore your options.

Once your inserts are validated, they are manufactured and delivered to you, and either inserted and/or glued in your cases, or separately, according to your needs and technical constraints.

Both installation methods have advantages:

Inserts inserted and not glued: you can place your inserts as you wish and glue them at your convenience. This solution is also advantageous if you want to put your products directly in the inserts before placing them in the case. Cases with inserted, unglued inserts are also fully recyclable. You can easily glue them with neoprene glue or permanent adhesive.

Inserted, glued inserts: This type of assembly allows you to receive your cases ready and usable directly, which is a real time saver.

A case with inserts takes about 6 to 7 weeks after validation of the ready-for-printing acceptance to receive your cases. If you want to receive a prototype, you will need to add a few weeks, so it is important to start the search process early enough, especially if you have a deadline.

Dense blue foam cushioning with a rigid finish, allowing perfect retention of the case contents, and optimal and satisfactory storage. This insert was created to accommodate a selection of tools and the blue colour was chosen according to the customer’s graphic charter.

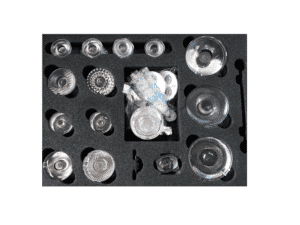

This black foam insert, designed for Gaggione Optics to hold and present samples to its customers, meets many technical specificities including the shape of the spaces (with finger grips to be able to grab the collimators), the texture (so as not to scratch the collimators’ optical quality), the depths (each product has a different dimension), etc.

This black thermoformed insert was designed to accommodate a series of kitchen utensils including knives. Particular attention has therefore been paid to the safety and support of the knives. A thermoformed insert allows easy cleaning of the inside of the case to meet the hygiene standards on which the food sector depends.

This semi-dense foam insert was specially designed for this small tool kit inserted in the K2 model. This box is a small model, so the insert is rather fine and dense, allowing a smooth finish and firm support. The shallow depth of this insert allows the user to easily pick up the tools and the identifiable shapes allow for instinctive storage.

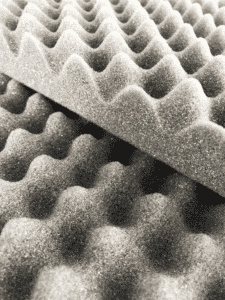

Diamond pattern foam is available in several densities and thicknesses to support objects of all sizes and weights. This foam provides two possibilities:

Two diamond pattern foam inserts placed in the lid and the bottom of the case provide lasting support at a rather low cost.

A diamond pattern foam insert and a foam insert cut to the shape of the products. This solution allows the best protection of the contents of the case while supporting the products and tools in all circumstances, including when the case is transported.

The height of the embossing is adapted to the different heights of the products positioned in the case.

In conclusion, we offer several insert options to support, protect and showcase the entire contents of the case. These customised inserts allow the solution we offer to be adapted to your needs and your technical constraints.

With Gaggione E-plasticase, you can apply a logo, image or text to the case exterior by screen printing, digital printing or hot stamping. To obtain a costed quote with branding and an insert, please send us in addition to the information requested above:

A vectorised file in EPS, AI, DXF or IGES format of the design you want to print

The reference(s) of the branding colours (PANTONE is preferred)

If you require text, the desired font.

To learn more about exterior branding, check out our blog post.

Discover the GAGGIONE E-Plasticase catalogue.

Format, size, colours… what packaging would suit your project?

For almost 50 years, GAGGIONE has been creating and manufacturing plastic cases. It began with a custom-made case for a company who wanted to sell a kit of several products in a solid carrying case. Our dedicated brand name to packaging, PLASTICASE, created in 1976, now offers a large range of more than 30 plastic cases and boxes in different designs, colors and finishing. To make the most suitable case to your image, our specialists will offer you the best solution to present, protect and carry your products efficiently. Gaggione is well-known all over the world for its quality, efficiency, and reactivity! Trust the E-Plasticase team who will make with you the most successful packaging you ever had!